Discover

Increased

Production

Efficiency.

70

75

Polyethylene Film

80

Maykom Plastics, which always aims at high quality, systematically researches the developments in the sector and presents the innovations to its customers. It carries out its work with dedication, stability, and determination, with the responsibility it feels towards its customers.

420.000 TONS

42 COUNTRIES

3 FACTORIES

Maykom Plastics; has more than 30 years of experience and expertise in the production of filled intermediates and polymer additives. Maykom, which renewed its production lines with the world's leading machinery and equipment in 2017, offers competitive and suitable solutions according to the needs of its customers. It produces special solutions for every sector with its qualified products, flexible production, fast service, strong technical infrastructure and human quality in both standard products and special works.

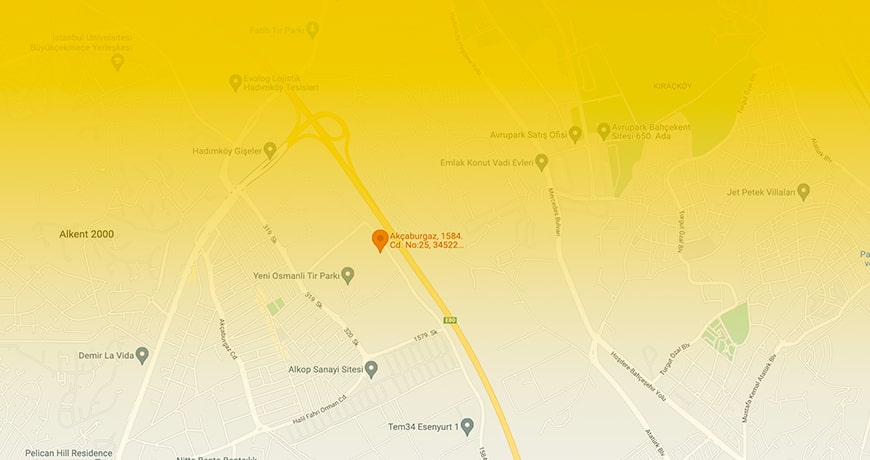

Factory Address

Akçaburgaz Mh. Ahmet Yesevi Cd. No:21/1 Esenyurt / İstanbul

info@maykom.com.tr +90 212 886 63 22

CONTACT US!